Most people have no idea what goes into making the products they know and love. As a company dedicated to improving lives through hardware, we want to change that. In this 4 part series, we’re pulling back the curtain on our manufacturing process and giving an inside look into what goes into building the Smart Vent. Check out the other blog posts here: Why China is Essential, Good, Fast, Cheap -- Choose Two, and Making It Work.

Last week we showed you how our most recent trip to China was all about quality assurance. As an example of what comprises this kind of obsession with quality, here’s a look at what went into designing just our battery compartment.

Many of our customers live in humid environments or near the ocean and will use our vents in their bathrooms with steam rooms or showers. We’re designing our product for the long haul and moisture can cause battery powered products to corrode over time.

Typically, high quality modern batteries — like the Duracell Duralocks we provide with our Smart Vents — won’t leak like the battery pictured above. However, after a few years of operation, users are likely to replace them with whatever they have on hand. Our goal at Keen Home is to minimize chores in the home, and cleaning out corroded batteries is not our (or your, we imagine) idea of a fun time. We needed our batteries to be sealed yet replaceable; so we created a novel battery cartridge that opens and presents the batteries for easy replacement, but creates a watertight seal when closed. Creating this case required 14 different designs and prototypes before we felt we got it right (8 of those prototypes are pictured in the image at the top of this post). Some were sealed but confusing to use. Some were straightforward, but took up too much space

One of our watertight battery cartridges.

We also sealed our PCB with a thick, humidity-proof conformal coating. On this last trip, we replaced the hand worked process of masking off the circuit for water sealing with a more precise automated process.

This level of detail and process orientation is part of how we guarantee that every vent is up to specification for moisture.

But this is just one aspect. The battery compartment also has to:

- Seal out moisture

- Efficiently conduct power to the board

- Eject smoothly for battery replacement

- Keep batteries from falling into a floor vent if dropped

- Handle reversed batteries without leaking

Ultimately, each design iteration had to pass a battery of tests.

When it comes to battery life, every milli-amp hour counts. A milli-amp is a unit to measure energy drawn from batteries. In many ways, when you buy a battery, you’re buying milli-amp hours (the amount of time a battery lasts during energy draw). The high capacity batteries we supply with each Smart Vent come with a total 5,700 milli-amp hours. When you run out of milli-amps, your batteries die and need to be replaced.

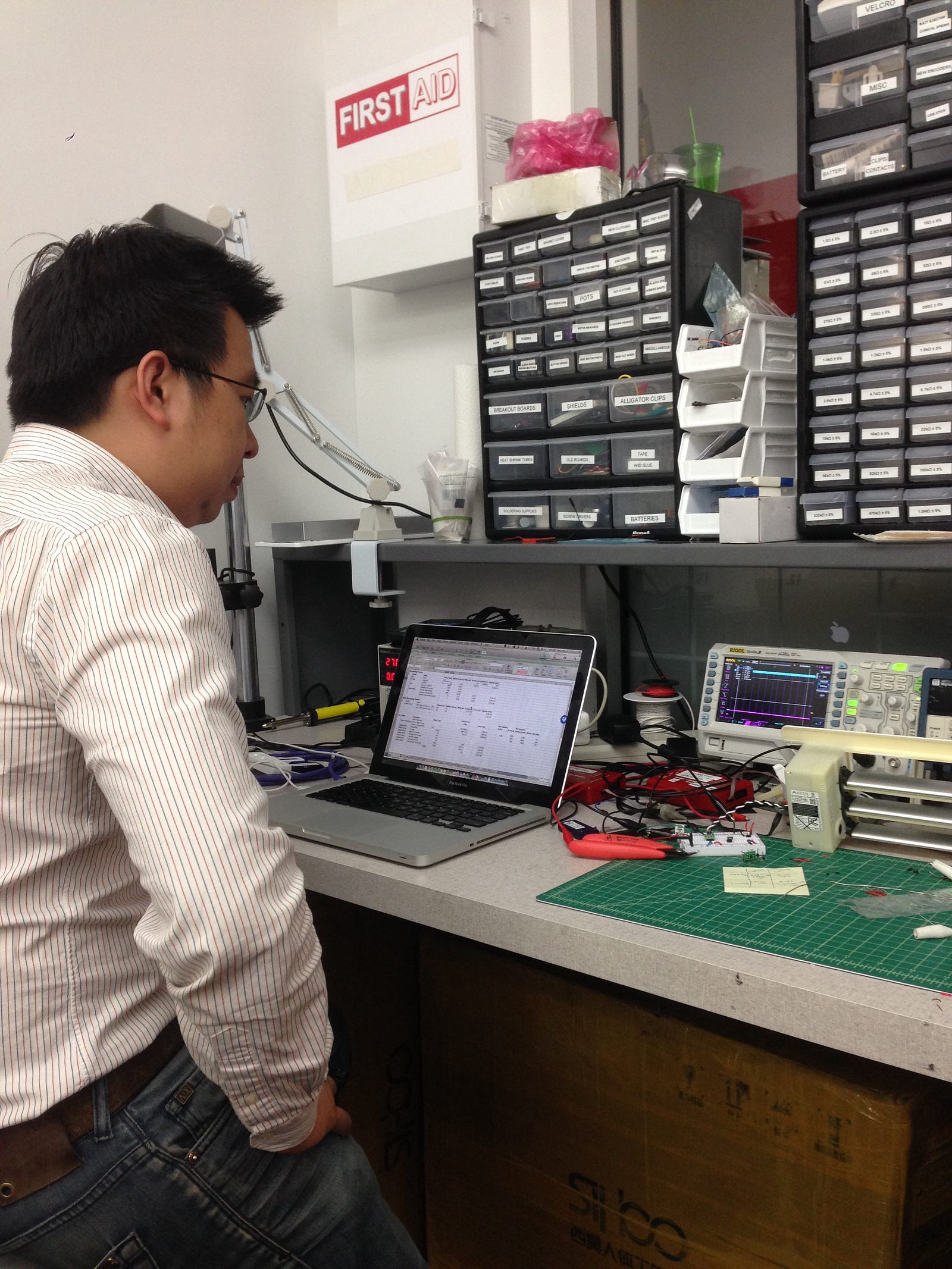

Replacing batteries is another chore we can’t stand. Sam, our senior electrical engineer, has been working through each line of firmware to count where each milli-amp goes and to optimize them.

Every component counts too. The springs in the battery cartridge allow for a smooth ejection while also raising every other battery to make replacement easy, but they have slightly higher resistance than we want and will cost us coulombs. We ended up gold plating our springs to get a few extra months out of each pack.

This is what goes into ensuring the quality of just one aspect of one part of the Smart Vent. There are hundreds of other details that require testing and reworking to ensure we manufacture the best product possible. Next week we’ll discuss what is arguably the most important part of any smart device: the strength and reliability of wireless radio signals that allow them to communicate with each other, your phone, and other devices on the internet.

This post was written by Will McLeod, Keen Home’s Technical Co-Founder on May 29, 2015.