Most people have no idea what goes into making the products they know and love. As a company dedicated to improving lives through hardware, we want to change that. In this 4 part series, we’re pulling back the curtain on our manufacturing process and giving an inside look into what goes into building the Smart Vent. Check out the other blog posts here: Why China is Essential, Batteries Included, and Making It Work.

Past trips had built up to this one. Initially, we spent countless hours researching and ranking potential partners, then in China we visited a half a dozen factories to decide who to work with. Once we had a great partner, subsequent trips had us collaborating throughout the prototyping stages to refine our design for cost reduction, quality, and volume manufacturing. During one trip we even laid out our logistics and supply chain. There is no substitute for having your feet on the ground in China.

There is no substitute for having your feet on the ground in China.

This trip, the focus was squarely on quality. Quality is composed of specification, performance and compliance. The devil is in the details and with a hardware startup, every detail matters. An unintentional radiator can cost you FCC certification. And if it’s not certified, it doesn’t ship.

There is a saying in Engineering, “Good, Fast, Cheap: Choose 2.” Quality takes time. Most Chinese manufacturers are capable of delivering quality, but often only see pressure to reduce price and lead time. Young companies often run into trouble when they don’t communicate their commitment to quality to their partners in Asia, but only make their cost concerns known. This trip was the latest in a series of ongoing efforts to make our focus on quality clear.

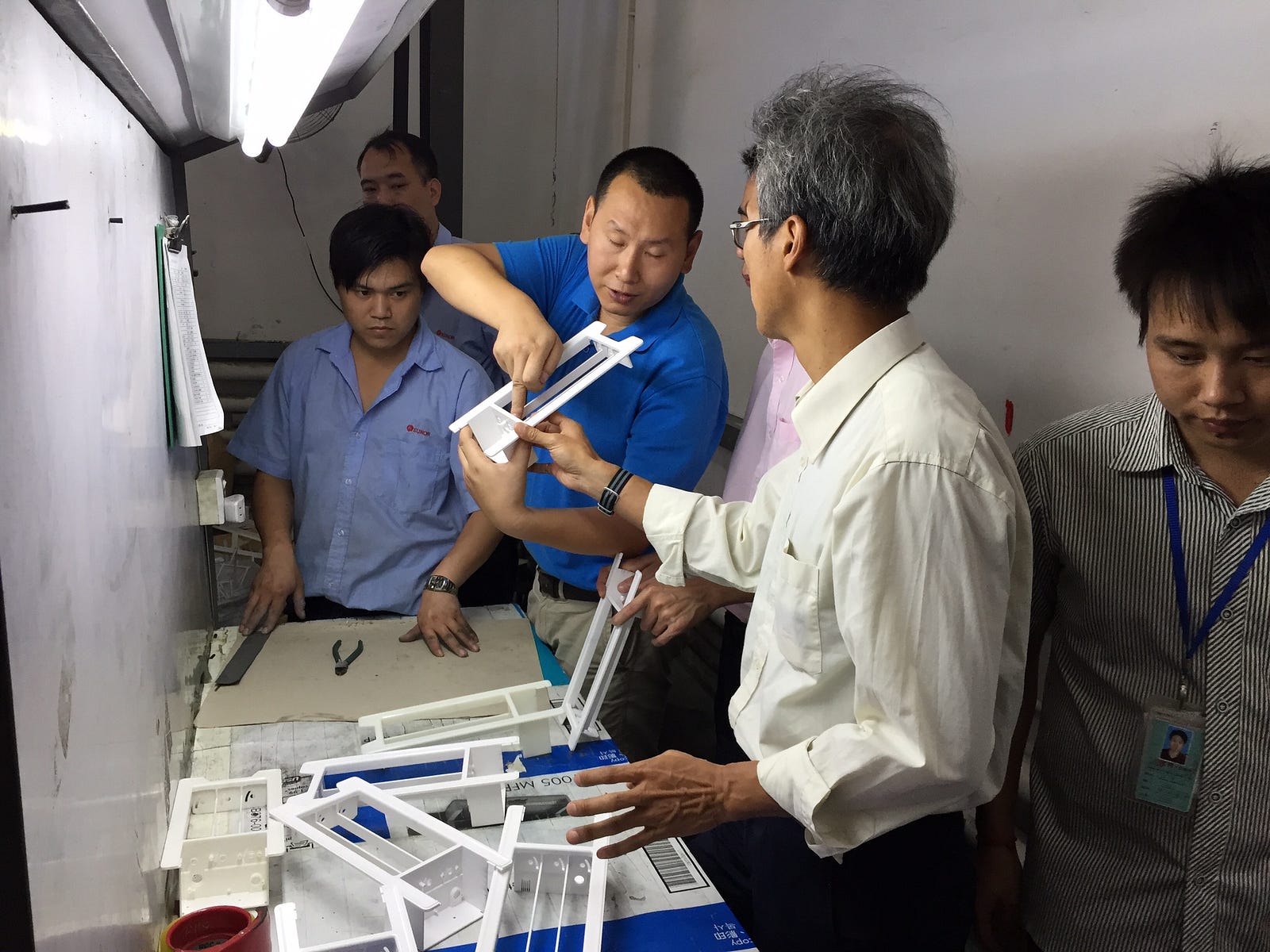

On the ground, our first stop was our tooling house. In injection molding, you start with pellets of plastic, heat them to melting and inject them with several hundred tons of force into enormous steel cavities that shape the molten plastic. As they cool, the Smart Vent chassis takes shape. 10 tons of carved steel were ready for inspection and poised to form those parts of at high volume.

The first parts off the tool, T1s, often have various visual defects. Sink marks, knit lines, and jetting are a result of improper heat dissipation, cooling and plastic flow. Each defect is identified, marked as unacceptable and corrected with changes to timing, pressure and temperature, as well as run through a system of hydraulic cooling lines. After a few days work, our tools were producing parts that were ready to move on to the next battery of specifications and refinements. We even manufactured a clear version of the Smart Vent to let us watch the mechanics mesh and ensure proper fits.

Our steel and aluminum components are extruded as liquid metal through a shaped hole in a steel plate at hundreds of tons of force. Surface finish, rust protection and repeatability are all tested to spec at our manufacturer through a battery of stress tests including a 24-hour salt spray.

Next, we started implementing our quality control practices at our main factory. Leading up to our trip, we identified over 150 critical test criteria to ensure performance and quality of each Smart Vent. These tests span every aspect, from aerodynamics to ensuring that every part (even the label) can withstand a multitude of cleaning agents. The result is a resilient, easily cleanable Smart Vent — our herringbone faceplates are even dishwasher safe!

Building the best product possible is our top priority. By ensuring clear communication with our factory partners and stressing our commitment to quality, we are able to maximize each factory visit and ensure cost is not the primary focal point in the work they do.

This post was written by Will McLeod, Keen Home’s Technical Co-Founder on May 21, 2015.